The whole production and research base takes process and equipment as the core, takes data as the basis, relies on research and development, manufacturing, supply chain, etc., and is committed to building a safe, efficient, green, and low-carbon intelligent manufacturing factory. Production processes and supply chain systems are automated, orderly, transparent, visualized, and lean with the help of big data. At the production site, production data is collected every 5 seconds to build a digital model of the full life cycle of the product, and through the Internet of Things technology, the quality of the whole process of the product is traced.

At the same time, the construction of the base adopts a series of new environmental protection technologies, green energy-saving facilities, and low-carbon environmental protection new materials, aiming to reduce energy consumption, create a highly intelligent and automated "green factory", realize the intelligent and automated management of factory operation, minimize the impact on the environment, and improve the efficiency of resource utilization.

Covering an area of 1800 square meters, it shows the company's deep heritage and excellent product research and development strength.

Its main functions include brand history display, corporate culture promotion, patent, and award certificate display, numerous technical patents, and authoritative awards at home and abroad, highlighting the company's strong R & D innovation ability and leading position in the industry, is a strong endorsement of the company's technical strength and professional quality.

The full range of Philips and Elboni products are neatly displayed, fully presenting the rich product line and excellent performance, innovative design, and intuitive appreciation of the unique charm and advantages of the product. The core parts display area in-depth analysis of the excellent quality of the product.

Research And Development Base

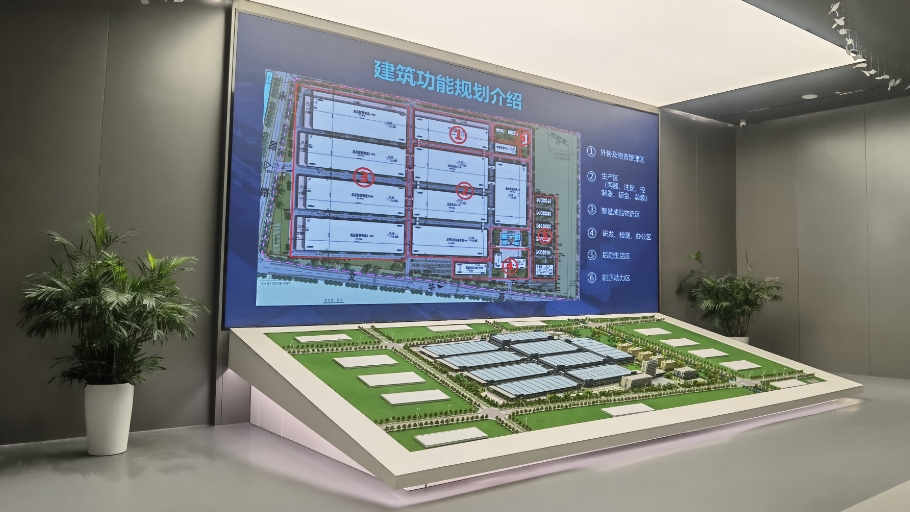

Elboni Electrical Appliance is located in Nanqiao Economic Development Zone, Chuzhou City, Anhui Province, located in the Yangtze River Delta integration of strategic development areas, inter-provincial junction, with strong home appliance industry atmosphere and fast and convenient transportation. As the only research and development base of Philips air conditioning in the world, its main function is to develop and produce Philips full range of household air conditioning and central air conditioning products. The total construction area of the first phase is 450,000 square meters, The overall layout of the production and research base covers R&D centers, intelligent production workshops, automated warehousing and logistics centers and other supporting facilities.

The experimental center covers an area of 12,000 square meters, standing three layers of modern testing facilities, more than 50 professional laboratories, and more than 200 fine test projects, every Philips air conditioning is strictly checked here, is the cutting-edge technology, but also the fortress of quality control.

Total construction area of more than 20,000 square meters. The production parts cover the whole series of air conditioning models, including precision injection molding, gas-assisted molding, high-light molding, two-color injection molding, etc. The workshop is equipped with a mold library, mold machining area, small, medium, and large injection molding processing area, central feeding system, raw material recovery area, equipment spare parts area, and intelligent storage area. The injection molding branch has the leading processing and molding technology in the household appliance industry to provide the company with high-quality and efficient products.

Sheet metal factory is a modern factory processing air conditioning structural parts, covering stamping, CNC, spraying three plates, plant planning area of 50,000 square meters, of which the first three household air conditioning sheet metal stamping lines and a household air conditioning production spraying line, That is, 800 tons of three-dimensional automatic punching line, 500 tons of continuous die production line, 5*250 tons of multi-robot production line, home air conditioning automatic spraying line, with air conditioning industry-leading technology. The sheet metal factory shoulders the important mission of quality assurance and annual production of the Philips air conditioning base.

Evaporator and condenser factory

The Evaporator and condenser factory is a modern factory processing the core components of air conditioning, the two units we usually say "evaporator and condenser", in the air conditioning are used to make the refrigerant and air heat exchange device, shoulder the Philips base air conditioning annual output and high-quality level control of the important mission. Plant area planning of 50,000 square meters, with the industry's leading imported automatic fin production line, non-shrink expanding machine, automatic three-dimensional bending machine, and other high precision processing equipment, equipped with a key start and another intelligent management system to achieve two-unit production, intelligent pipe expansion machine, helium inspection automatic recovery and other intelligent production.

The total construction area is more than 50,000 square meters, and each production line will have 1 air conditioner every 7 seconds. The main production of household, and commercial split inside and outside the machine. The whole machine assembly, inspection, operation test, packaging, and other links are completed on this production line.

The overall finished product warehouse is composed of four intelligent logistics workshops for finished products, which can realize the intelligent management of the whole logistics process such as warehousing, storage, and delivery.

Construction area of more than 100,000 square meters. Finished product logistics adhering to the "fast in and fast out" principle, through intelligent management systems, and mechanized operation, greatly improving the efficiency of delivery. Using the cutting-edge WMS (Warehouse Management System), under this automated nerve center, the location of every air conditioner and every logistics path are accurately recorded. All processes are closely monitored, improving storage efficiency while greatly reducing damage caused by secondary handling.